Have you ever had an incredible idea for a new product that could solve a problem? That’s just another day in the classroom for graduate and undergraduate students in BEGR 411, “Integrated Product Development,” taught by Jamal Ghorieshi, professor of mechanical engineering.

“It is simple, you learn by practicing. For instance, you learn how to drive a car by actually driving one,” said Ghorieshi. “I think Product Development is the type of a course that provides an opportunity for students to learn by practicing.” The students agree.

“To be able to put an idea into a tangible form, really making something solid and not just imagining it, is great,” said Nickerson Demelfi, a graduate bioengineering student from Newbury Park, California, who is working with his classmates on a device that stirs liquids using vibration. “Thinking about something that felt impossible and making it possible feels amazing,” said Alexis Vélez, a graduate mechanical engineering student from Caguas, Puerto Rico.

One of the most unique parts of this course is how subject matter experts from a variety of disciplines are brought in to enrich the already hands-on experience, working with students to design plans for bringing a product to market. This innovative teaching approach helps Wilkes University’s College of Business and Engineering stand out.

Guest lecturers this semester included Brad Barry, associate director of creative services, and Mandy Pennington, director of digital strategy, from the University’s Marketing Communications team, as well as Anna Ma, assistant professor of marketing, and Ken Wang, associate professor of finance, from the Sidhu School of Business & Leadership, Brian Sacolic, director for the Farley Library, Xiaoming Mu, associate professor of mechanical engineering, Yong Zhu, associate professor of mechanical engineering, and Jerry Lisman, chairman and CEO of operating company Lisman Holdings Inc.

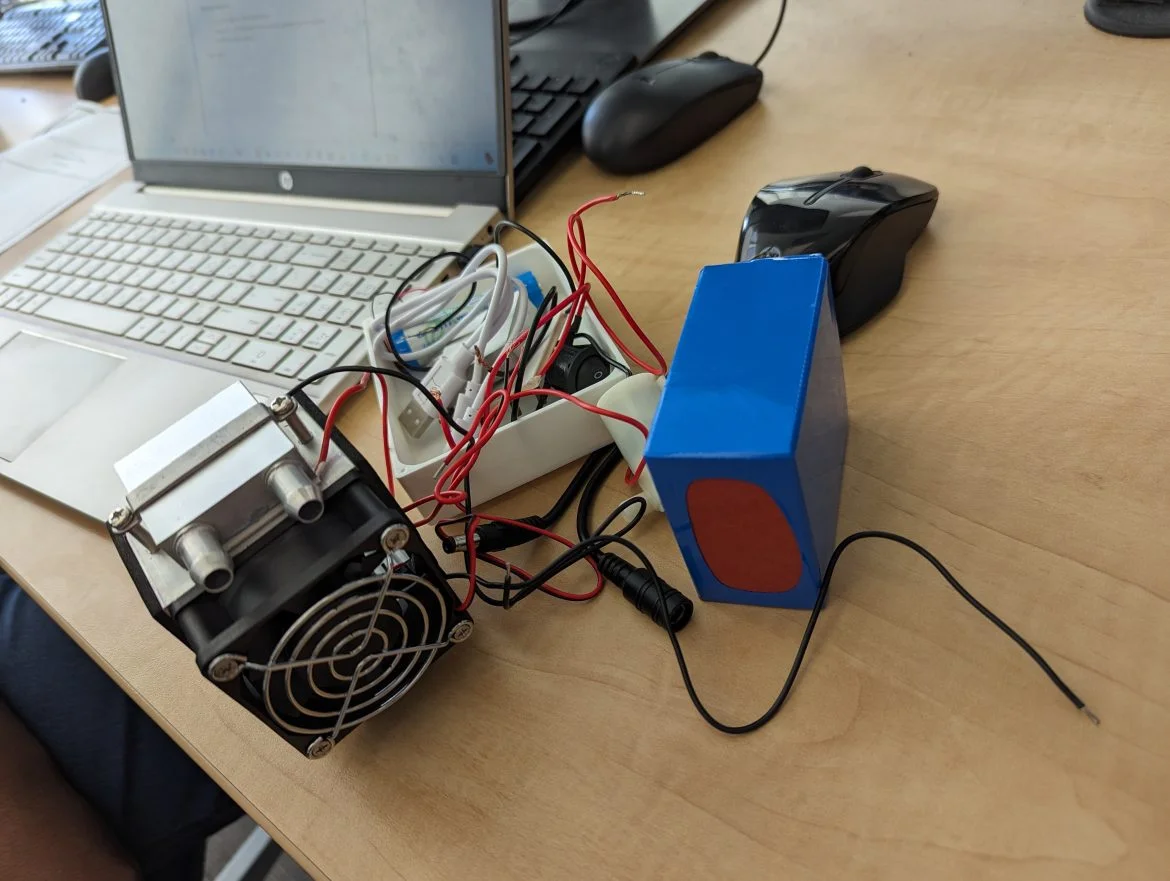

It all starts with an idea. The goal is to choose something that can benefit society, then work together to refine and prototype each invention. “It’s good to make things that help people,” said Harfan Alahmary, a graduate mechanical engineering student from Riyadh, Saudi Arabia, who is collaborating with classmates to develop a cooling hat that can offer much-needed relief in hot weather. “I’ve really enjoyed working with my team.”

For some, this is the first time they’ve ever experienced the prototyping process in a hands-on way. “[I’ve] never 3D printed anything before,” said Frank Yuscavage, an undergraduate mechanical engineering student from Hanover Township, Pennsylvania, working with his classmates on a collapsible hair clip that’s more comfortable for everyday wear. “We have a nice mix of creatives and engineers in our group,” said Miquela Langan ’21, a bioengineering graduate student from Hanover Township, Pennsylvania. “The interdisciplinary aspects of this course have been awesome.”

In this semester’s class, there are four student groups working on four distinct products: a coffee cup carrier to make beverage service at home easier, a collapsible hair clip made from flexible material, a cooling hat designed for extreme climates and a vibrating device meant to stir liquids used in life sciences experiments without exposing them to contaminants.

Once each product is prototyped, it goes through a series of refinements to ensure that it’s ready to take to market. Students also perform a patent search to see what inventions related to their projects may already exist. “The process is inspiring me to patent [a product] in the future,” said Ahmed Alsahli, a bioengineering graduate student from Jeddah, Saudi Arabia, who is working on the coffee carrier project.

Plans for manufacturing and producing the device at scale follow, along with the development of marketing and sales strategies, including the creation of videos to sell their products to target audiences. This allows students to fully understand not only how their products offer value to a particular market, but what demand may exist. “Figuring out what product is the hard part but converting to sales is the hardest part,” said Ghorieshi.

“It made me think about starting a business, different projects and how to go from start to finish,” said Mohammed Almadhor, a mechanical engineering graduate student from Aljouf, Saudi Arabia.The class gives students a deeper understanding of products beyond clicking the “add to cart” button. “Because of this experience, students will see goods in a new light,” said Ghorieshi. Students agree that the process of developing a new product from scratch has been an incredible learning opportunity. “It made us all think outside what we’ve known,” said Molly Yushock ‘22, a graduate bioengineering student from Ashland, Pennsylvania.